Wire Mesh Belt Conveyors for Washdown, Cooling, and Heating Operations

Weimer offers complete wire belt conveyor systems, as well as replacement components, including wire belts, gearboxes, bearings and pulleys.

When products need to move through heat, cold, or heavy washdown areas, wire mesh belt conveyors deliver dependable performance. Each system can be custom engineered with different wire styles (including flat wire, round wire and balanced weaved), materials, and configurations to fit your exact requirements.

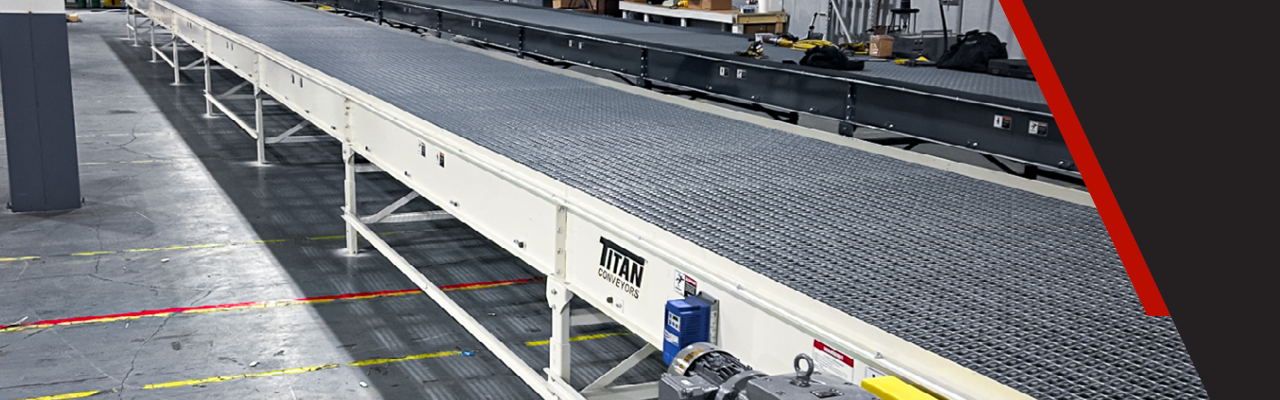

Pictured are flat wire mesh belt conveyors our team provided for a candle manufacturer, helping streamline the cooling process.

Why Choose a Wire Belt Conveyor

- Handles heat and cold: Ideal for baking, cooking, washing, drying, heating, cooling, or spraying products at very high or low temperatures.

- Open mesh design: Promotes full airflow and fluid drainage so parts cool, dry, or rinse quickly without pooling.

- Rugged and reliable: Steel belts resist melting, cracking, or tearing, even under harsh conditions.

- Easy to clean: Smooth surfaces and open spacing make sanitation fast and simple. Stainless steel wire belts are ideal for food and chemical applications.

Common Applications

- Heating, drying, or cooling items

- Food product baking, washing, or processing

- Parts washing and rinsing systems

- Coating, spraying, and chemical processing lines

Built for long life, low maintenance, and consistent performance, wire mesh belt conveyors provide the durability and temperature control your operation demands. Contact our team to discuss your application and learn how wire mesh conveyors can improve efficiency and reliability in your process.