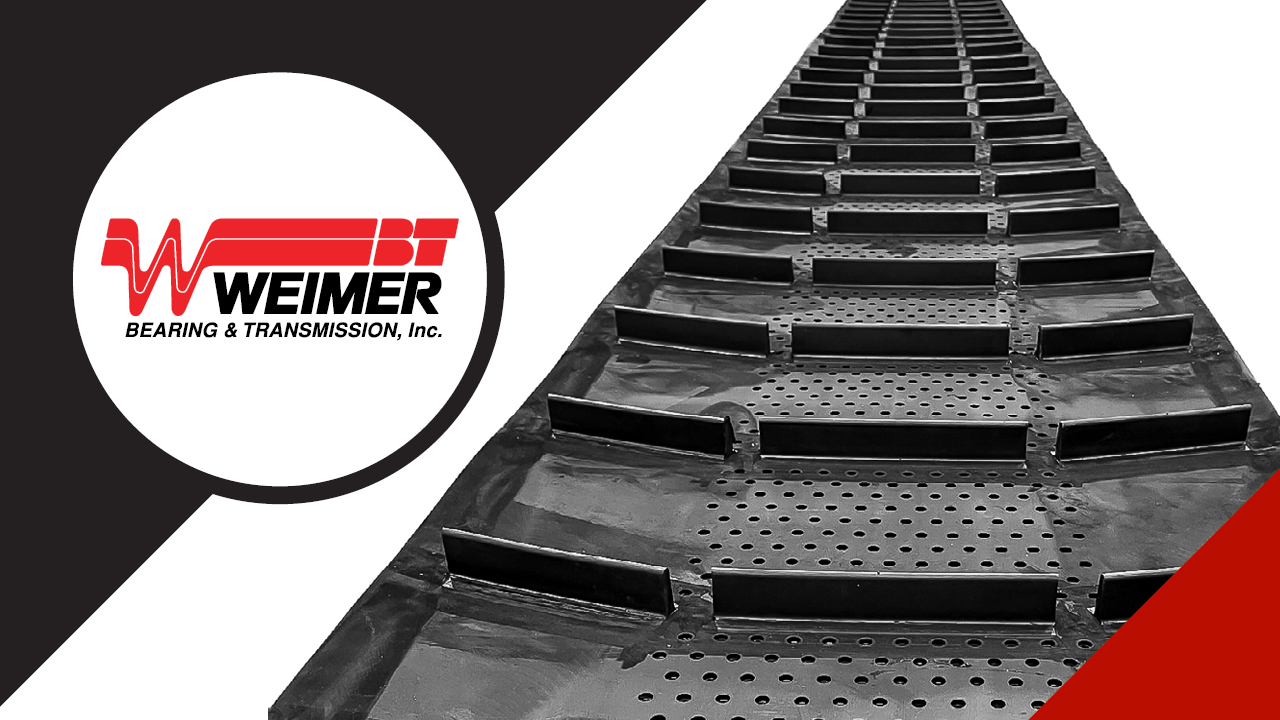

Conveyor Belts for Dewatering and Filtration Applications

At Weimer Bearing, we provide dewatering and filtration conveyor belts engineered for industries where efficient moisture removal and liquid drain separation are critical. These belts are perforated and made with an open structure to improve material handling, reduce costs, and enhance operational efficiency.

Applications of Dewatering and Filtration Conveyor Belts

- Mining Slurry Dewatering Belts – Reduce water content in mining slurries for safer, more efficient transport and lower operational costs.

- Wastewater Treatment Sludge Dewatering Belts – Manage industrial and municipal sludge efficiently, achieving cleaner water discharge and reduced disposal volumes.

- Food Processing Dewatering and Filtration Belts – Ideal for fruits, vegetables, seafood, and meat. Remove excess moisture to improve product quality, shelf life, and packaging readiness.

- Pulp and Paper Slurry Dewatering Belts – Remove water from fiber slurries to increase throughput, reduce drying energy use, and improve overall production efficiency.

Built to Your Specifications

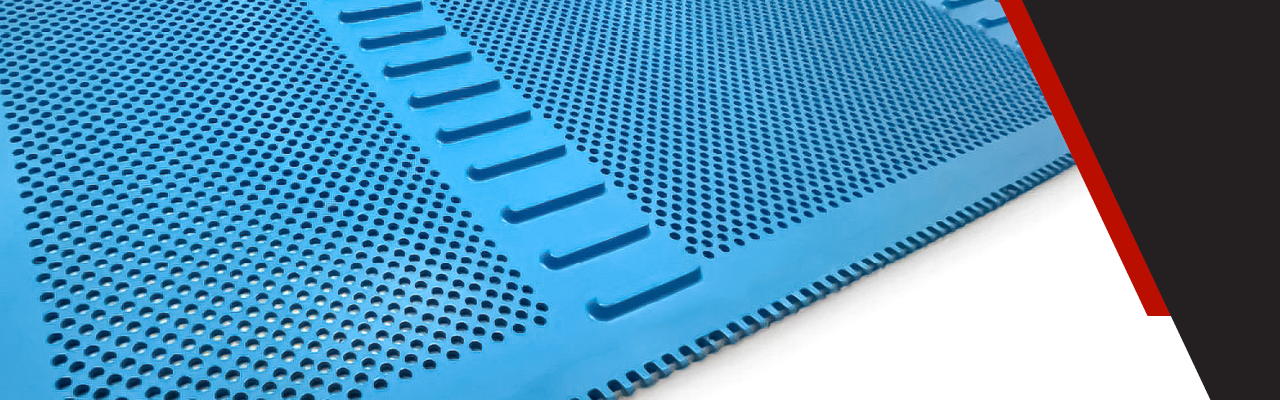

Weimer Bearing fabricates custom dewatering belts that are available in a wide range of widths, materials, and constructions to suit your system needs. They feature engineered punched openings that allow liquids to pass while retaining solids. Options include various groove designs, drainage patterns, and belt constructions to match specific materials, flow rates, and operational requirements.

- Drainage Hole Patterns – Single or multiple holes per groove; repeated patterns across belt width; holes straddle ribs between grooves.

- Groove Shapes – V-shaped, U-shaped, or round; grooves cut or ground into the top cover.

- Skirts – Various heights and styles to increase capacity and prevent spillage.

- Carcass Protection– Fabric-free zones around drainage holes and edges; solid rubber protects belt structure.

- Guides & Tracking – Bottom guides keep drainage holes centered and improve tracking; multiple guides possible across belt width.

- Custom Features – Belt width, length, thickness, groove spacing/depth, and material compound can be tailored to application.

We're here to help! Find a location near you or contact our knowledgeable team for personalized assistance.

Find a Location | Contact Us | Request a Quote